Bottling wine might look like one of the easiest parts of winemaking—machines are doing much of the work, after all—but the ease of muscle during bottling season is replaced with a barrel full of anxiety because it truly is the most critical winemaking decision we make after when to harvest the grapes, and it requires years and years of expertise to perfect the complexities of placing a delicate wine into its aging vessel.

Three reasons why bottling wine is serious business:

- Bottling is the last step in the winemaking process to ensure that the wine tastes exactly how we want

- Bottling wine with high-tech equipment reduces the amount of oxygen that could get into the bottle during bottling (oxygen exposure would cause the wine to age prematurely)

- Bottling wine with the best equipment is more gentle on the wine, allowing them to avoid significant “bottle shock” and to be more expressive in aroma and flavor sooner (after six months to a year)

This creative, snappy GoPro video outlines the journey a wine bottle takes, from being filled with Jordan Cabernet Sauvignon to being corked, labeled and boxed. The most important steps for bottling wine occur in a sterile cabin, made of glass, which has the same microbial protection as a hospital emergency room. You’ll see this glass cabin throughout the video. Enjoy this 1:49 ride at a viewpoint you likely haven’t seen before – from a wine bottle’s point of view. (This GoPro video was created by Thomas Remiyac on our cellar team, who entered this video into our first employee video contest last year.)

There are several critical steps in the winemaking process to ensure the highest quality and integrity when bottling wine, both before and during the filling of wine bottles:

Before Wine Bottling

- Every December, glass bottles are ordered. All 750ml bottles for Jordan wines are made in California; large-format bottles are made in France and Italy, the countries with the most experience and volume.

- Every February, wine corks are ordered from Portugal and undergo a rigorous quality control process as noted in our blog about how wine corks are made and tested.

- In early spring, the winemaking team tastes the new vintage and decides when it should come out of barrel and when the master blending before bottling should occur. During the master blending session, we decide if the Jordan Cabernet should be egg-white fined and if any lots should be declassified. Then, only the top lots go into the master blend that we bottle.

- Every May, cork quality testing continues once the wine corks arrive into California from Portugal. See our blog post, 10 Fun Facts about Jordan Wine Corks.

- More often than not, we egg-white fine Jordan Cabernet Sauvignon. That’s the last step before bottling wine for our singular red. Egg whites help soften the tannins and polish the finished wine. Learn more about egg-white fining in this video blog.

- For a month leading up to the summer bottling season, we train staff, sterilize our state-of-the-art bottling line (watch a time-lapse video of its construction), run tests and make sure that all the equipment is in perfect working order before we begin bottling wine.

During Wine Bottling

- Quality control is a big part of bottling wine throughout the process, even though machines are helping us do the heavy lifting. It takes 10 people working nine hours per day for six weeks to bottle each vintage of Jordan Cabernet Sauvignon (Jordan Chardonnay takes nine days). During bottling, we run hourly tests on wine bottles to test corker vacuum, oxygen pick-up, fill levels, fill volume and diameter of the bottle necks (for proper cork insertion).

- Empty bottles are loaded onto the line by hand and shake their way into the bottle blower, where they are turned upside down. The bottle blower simply blows air into the inverted bottle to make sure that cardboard or lint from the wine case didn’t get inside.

- Empty bottles move into the filler to receive wine in a two-step process. First, they receive a spurge of nitrogen, which removes any oxygen from the bottle that could prematurely age the wine. Then the bottles are individually raised to the filler. By using a state-of-the-art wine bottle filler, the wine bottle fill levels (known as ullage) are highly consistent, which also helps avoid any low or high fills that could also lead to premature aging of the wine.

- Filled bottles turn through a six-headed corker, which can complete/cork six bottles at one time. The corker emits a small amount of nitrogen into the head space before pulling a vacuum and then inserting the cork. This process ensures, again, that no oxygen gets into contact with the wine. We have three employees watching the critical filling, corking and packaging portion of the line, making sure that the five optical cameras in our high-tech line are doing their precise jobs and refilling the line with supplies.

- Tin capsules are placed on the bottle in a two-part process. The capsules are placed gently on the bottle neck and then they go into a spinner, which tightens the capsule into place.

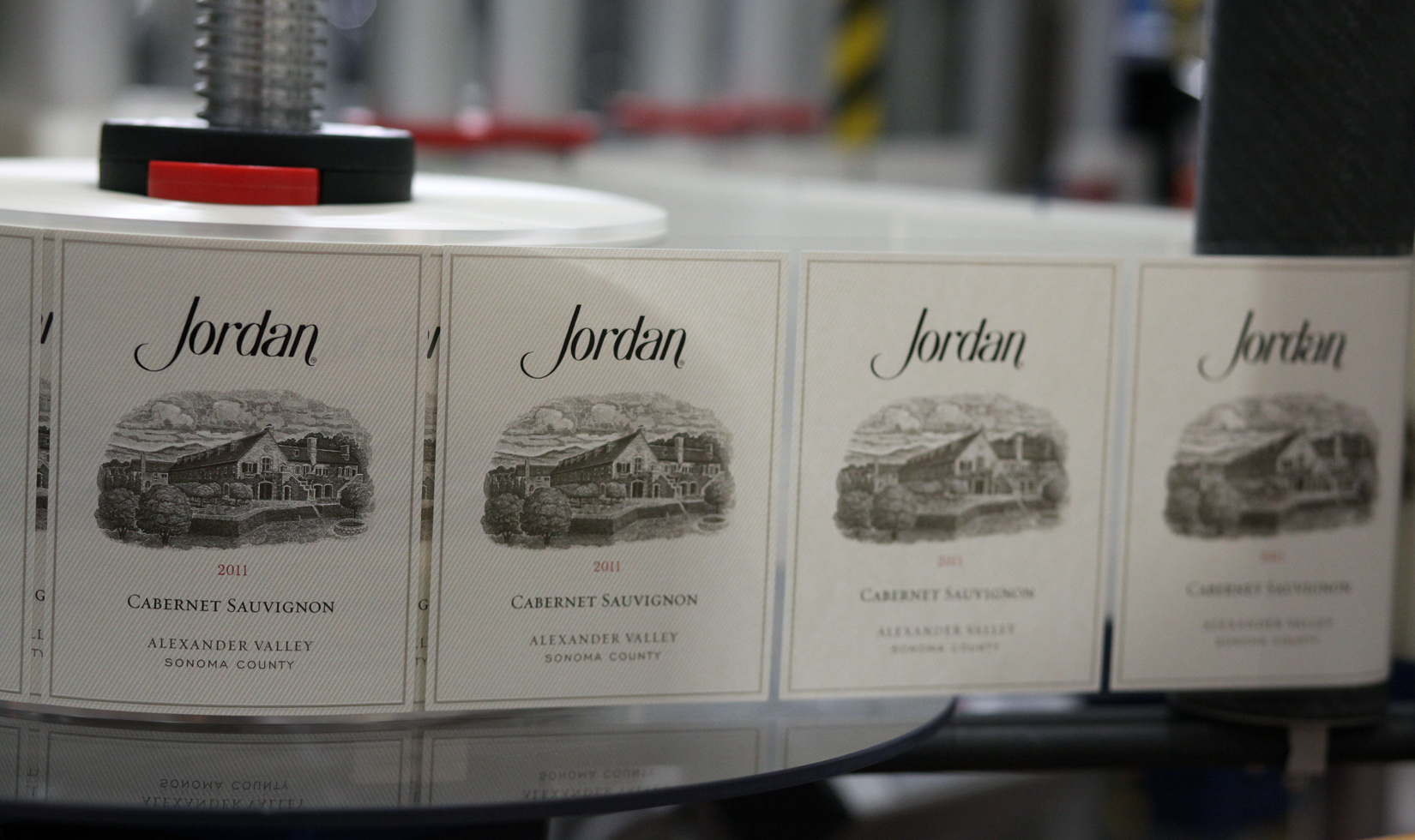

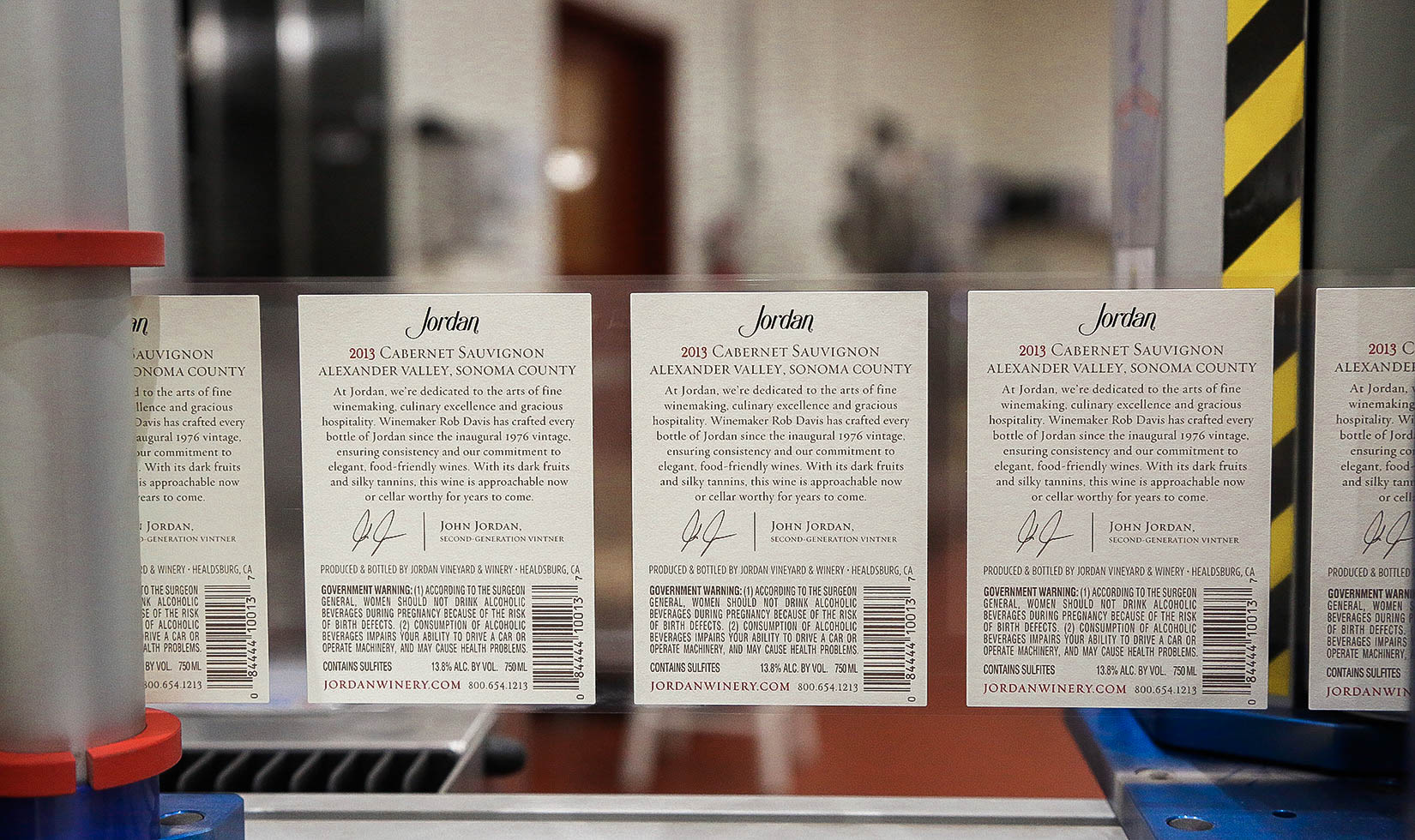

- Bottles move into the labeler portion of the line, where self-adhesive wine labels are placed on the bottle and then brushed around to adhere perfectly into place. Thomas, who made the above bottling wine video, spends most of bottling season watching over the labeling part of the machine, making sure that the labels are applied seamlessly and perfectly without stopping the line’s progress.

- Wine bottles then leave the sterile cabin and pass a rejection table, which is fitted with a camera that checks the fill level, cork integrity, capsule integrity and label placement. Bottles that don’t meet our standards are rejected and pushed onto a small conveyor belt.

- Approved bottles move into the case packer section of the line, which has soft-catch technology—guiding the bottles into the box gently. Ivan X watches over this process, making sure that the cases and bottles are perfect.

- Full 12-bottle cases are closed, flipped over and stacked with the neck down so that all the wines in the cases are in contact with the cork; employees place these cases on pallets to age for two full years before release for cabernet sauvignon (about six months for chardonnay).